Why Proper HardiePanel Installation is Critical for Pennsylvania Homes

Hardie board sheet siding installation requires careful planning, proper techniques, and strict adherence to manufacturer specifications to protect your investment and ensure warranty coverage. Whether you’re upgrading your home’s curb appeal or replacing weather-damaged siding, understanding the installation process helps you work effectively with your contractor and avoid costly mistakes.

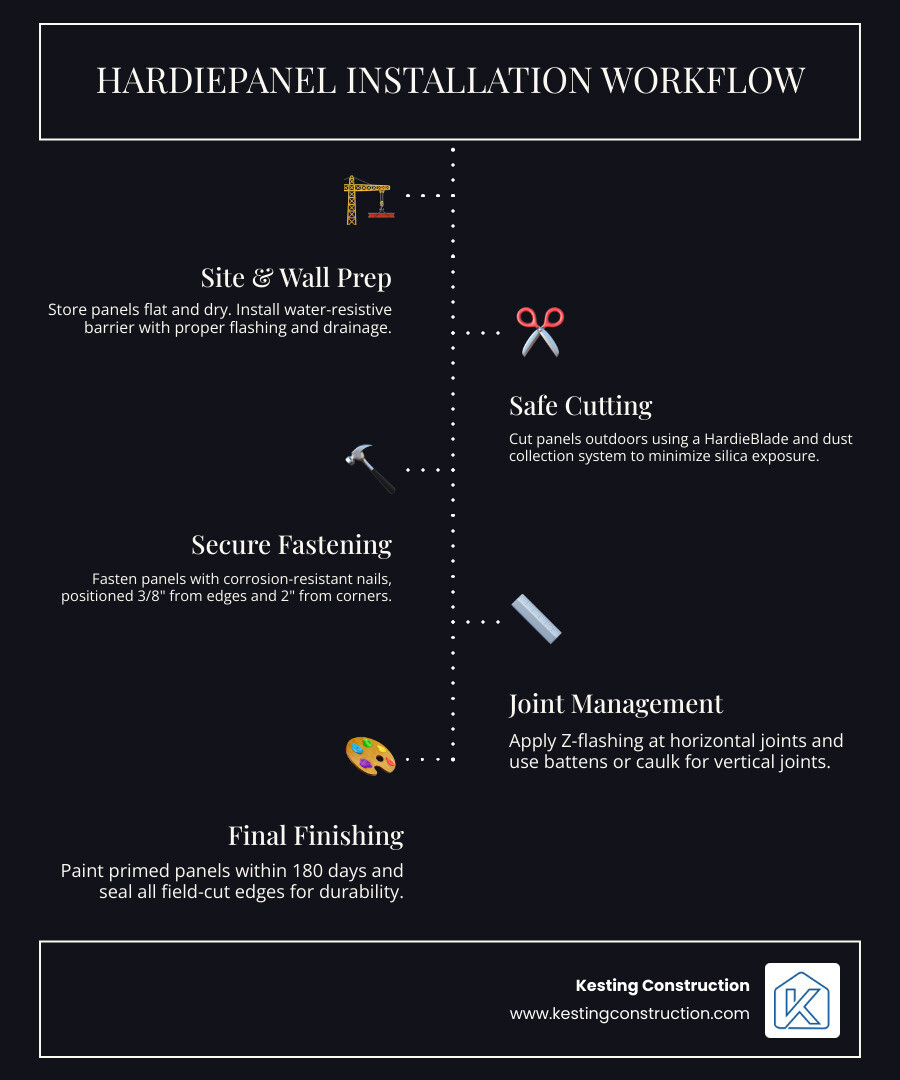

Quick Installation Overview:

- Prepare the substrate – Install water-resistive barrier and ensure proper drainage

- Cut safely outdoors – Use HardieBlade with dust collection to minimize silica exposure

- Fasten correctly – Position corrosion-resistant fasteners 3/8″ from edges, 2″ from corners

- Treat all joints – Apply Z-flashing at horizontal joints, battens or caulk at vertical joints

- Finish properly – Paint primed panels within 180 days, seal all field-cut edges

As James Hardie’s installation guide emphasizes: “FAILURE TO FOLLOW JAMES HARDIE WRITTEN INSTALLATION INSTRUCTIONS AND COMPLY WITH APPLICABLE BUILDING CODES MAY VIOLATE LOCAL LAWS, AFFECT BUILDING ENVELOPE PERFORMANCE AND MAY AFFECT WARRANTY COVERAGE.”

HardiePanel vertical siding offers Pennsylvania homeowners exceptional durability against our harsh winters and humid summers. But that durability only comes when the product is installed correctly. The fiber cement material contains crystalline silica, requires specific fastening techniques, and demands careful moisture management—especially in our climate.

This guide walks you through the complete installation process, from wall preparation to final touches. You’ll learn the critical safety precautions for cutting fiber cement, the approved fastening methods for both wood and steel framing, and the specific clearance requirements that protect your home from moisture damage.

Pre-Installation: Preparing Your Home for HardiePanel Siding

Before we even think about fastening a single Hardie board sheet siding panel to your home, proper preparation is paramount. The longevity and performance of your new siding depend heavily on the steps taken before installation begins. This includes carefully preparing the walls, ensuring correct storage of materials, and establishing an effective water-resistive barrier and drainage system.

Proper Storage and Handling Procedures

Imagine starting a project with damaged materials—that’s a recipe for disaster! That’s why we always ensure HardiePanel sheets are stored and handled correctly from the moment they arrive at your property in Harleysville, Yardley, or any of our other service areas in Pennsylvania.

James Hardie specifies that panels must be stored flat, kept dry, and covered prior to installation. Installing siding that is wet or saturated can lead to shrinkage at butt joints, compromising the integrity and appearance of your finished wall. When moving these robust panels, we always carry them on edge. This simple practice helps protect the edges and corners from breakage, ensuring each sheet is in pristine condition when it’s ready for installation. James Hardie themselves state they are not responsible for damage caused by improper storage and handling, so we take this step seriously.

Wall and Substrate Requirements

The foundation for a flawless Hardie board sheet siding installation is a properly prepared wall and substrate. Any irregularities in your existing framing, sheathing, or even foam insulation can “telegraph” through the new siding, creating an uneven and unsightly finish. Before installation, we carefully inspect and correct any such imperfections.

HardiePanel vertical siding is versatile, designed to be installed over various substrates:

- Wood Studs: The panels can be installed over braced wood studs spaced a maximum of 24 inches on center. This is a common framing method for many homes in Montgomery County and beyond.

- Steel Studs: For structures with steel framing, HardiePanel can be installed over braced steel studs. The studs should be between 20 gauge (0.836 mm) minimum to 16 gauge (1.367 mm) maximum, also spaced a maximum of 24 inches on center. Using studs outside this range might be too flimsy or too heavy for optimal fastening.

- OSB Sheathing: HardiePanel can also be fastened directly to minimum 7/16 inch thick OSB (Oriented Strand Board) sheathing or equivalent. This provides a continuous nailable surface for secure attachment.

Understanding the Siding Materials Pros Cons of your existing structure helps us tailor the installation method for the best results.

Water-Resistive Barrier and Drainage

Protecting your home from moisture is perhaps the most critical aspect of any siding installation, especially with Pennsylvania’s varied weather. A robust water-resistive barrier (WRB) is non-negotiable. This barrier must be installed in accordance with local building code requirements, creating a weather-resistant envelope that includes proper flashing around all penetrations and junctions.

Building codes, such as Section 1403.2, mandate that exterior walls must have a means for draining water to the exterior. James Hardie goes a step further, recommending the installation of a rainscreen—an air gap between the HardiePanel siding and the WRB—as a best practice. This air gap allows any moisture that gets behind the siding to dry out or drain away, significantly improving the building’s long-term performance and energy efficiency. For more on this, check out our insights on Siding for Energy Efficiency.

In our region, which experiences moist and sometimes severe wind-driven rain, the drainage requirements are stringent. A drainage plane with at least 90% drainage efficiency is often required, and a rainscreen with a minimum 3/8 inch air gap is highly recommended to effectively manage moisture.

The Art of Cutting Hardie Board: Safety and Precision

Working with fiber cement products like HardiePanel requires specific techniques and, more importantly, strict safety protocols, particularly when cutting. The material’s composition means that cutting generates fine dust containing respirable crystalline silica. We prioritize the health and safety of our team and your family during every hardie board sheet siding installation in Doylestown, Allentown, and all our project sites.

Recommended Cutting Methods

The method we use for cutting HardiePanel depends on whether we’re working outdoors or indoors, always with an eye toward minimizing dust exposure.

Outdoor Cutting (Best Practice for Maximum Dust Reduction):

When cutting outdoors, we position our cutting station so that airflow carries dust away from the user and others. The ideal method involves a circular saw equipped with a HardieBlade saw blade and an attached vacuum dust collection system. This combination significantly reduces airborne dust. Other acceptable outdoor methods include using a circular saw with dust collection or simply a HardieBlade, though these are less effective at dust capture. Fiber cement shears are also an option for smaller cuts.

Indoor Cutting (Limited Use):

For any indoor cutting, power saws are strictly avoided. Instead, we use shears or the score-and-snap method. This method involves scoring the panel with a utility knife and then snapping it along the line. The score-and-snap method is generally not recommended for products thicker than 7/16 inch.

You can find more detailed instructions and visual guides in the official HardiePanel Vertical Siding – Installation Instructions .

Critical Safety Precautions for Silica Dust

The dust generated from cutting fiber cement contains respirable crystalline silica. Prolonged or repeated inhalation of this dust is known to cause serious health issues, including cancer and lung damage. James Hardie and OSHA (Occupational Safety and Health Administration) have clear guidelines that we carefully follow to ensure safety:

- Work Outdoors: Whenever possible, all cutting is performed outdoors to disperse dust.

- Dust Collection: We always use dust collection systems with our circular saws. For construction sites, using a circular saw with a blade under 8 inches connected to a dust collection system can result in exposures below OSHA’s Permissible Exposure Limit (PEL) for respirable crystalline silica.

- Personal Protective Equipment (PPE): If dust controls are unavailable or for added protection, our team wears NIOSH-approved respirators (such as an N-95).

- Wet Methods for Clean-up: We never dry sweep dust. Instead, we use wet dust suppression methods or a well-maintained vacuum with an appropriate filter to collect dust. This prevents dust from becoming airborne again.

- Warning Others: We ensure that anyone in the vicinity is aware of the cutting process and takes precautions to avoid breathing the dust.

Compliance with OSHA standards is not just a recommendation; it’s a legal and ethical obligation we uphold to protect everyone on our job sites in places like Schwenksville and Pottstown.

Mastering the Hardie Board Sheet Siding Installation Process

Once the preparatory work is complete and we’ve safely cut our panels, the real magic of hardie board sheet siding installation begins: fastening the panels to your home. This stage demands precision in panel layout, correct fastener selection, meticulous joint treatment, and adherence to crucial clearance and flashing requirements. Our goal is always a secure, weather-tight, and aesthetically pleasing finish that will stand the test of time in Pennsylvania.

Approved Fastening Methods for a Secure Fit

The type and placement of fasteners are critical for the structural integrity and wind resistance of your HardiePanel siding. We ensure every fastener meets James Hardie’s specifications:

- Corrosion Resistance: All fasteners must be corrosion-resistant. While electro-galvanized fasteners are acceptable, James Hardie recommends using quality hot-dipped galvanized nails, or even stainless steel fasteners, especially for homes near large bodies of water, in coastal areas, or in humid climates like ours in Pennsylvania.

- Fastener Placement: This is key! Fasteners must be positioned a minimum of 3/8 inch from the panel edges and no closer than 2 inches from the corners. They should always be driven perpendicular to the siding and framing, fitting snugly against the siding surface without being overdriven or underdriven.

- Wood Framing: For wood studs, common siding nails (e.g., .091 in. x .221 in. x 1.5 in. or 2 in.) are typically used. We use pneumatic nailers for efficiency and consistent depth control, ensuring the nail head is flush with the panel surface.

- Steel Framing: When working with steel studs, self-tapping screws are the preferred method. These screws should have a cutting edge, and ideally wing tips, which bore out the fiber cement and then break off as the screw enters the steel. If screws without wing tips are used, pre-drilling may be necessary to ensure proper fastening. It’s crucial to hold the material tight to the steel framing when driving pins and to avoid hitting the fastener a second time with a hammer, as this significantly reduces holding capacity.

For a detailed look at our process, including specific techniques for our region, visit our James Hardie Siding Installation in PA page.

How to Properly Treat Joints in your hardie board sheet siding installation

Joints are potential weak points if not treated correctly, providing pathways for moisture intrusion. Proper joint treatment is therefore essential for a durable and weather-tight installation:

- Vertical Joints: HardiePanel vertical siding typically allows for a few options for vertical joints:

- Moderate Contact: Panels can be installed in moderate contact with each other.

- Battens: Covering vertical joints with battens creates a visually appealing board-and-batten look and adds an extra layer of protection.

- Jointers: PVC or metal jointers can also be used to cover vertical joints.

- Caulk: Vertical joints can be caulked, but this is generally not applicable for ColorPlus® Finish products, which have specific touch-up procedures.

- Horizontal Joints: At all horizontal joints—where one panel ends and another begins along a horizontal line—Z-flashing is an absolute requirement. This flashing directs water away from the joint and prevents it from entering the wall assembly.

- Caulking: For non-ColorPlus products, any joints that are not covered by battens or jointers, and where caulking is permitted, should be sealed with an elastomeric joint sealant complying with ASTM C920 Grade NS, Class 25 or higher, or a latex joint sealant complying with ASTM C834. This ensures a flexible and watertight seal.

Proper joint treatment, combined with expert James Hardie Trim and Soffit Installation, ensures a comprehensive moisture management system for your home.

Essential Clearance and Flashing Requirements

Clearances and flashing are vital details that prevent moisture from wicking into the siding or penetrating the wall assembly. We follow strict guidelines to ensure your home is protected:

- Ground Clearance: Adjacent finished grade must slope away from the building a minimum of 6 inches in the first 10 feet. There should be a minimum of 1 inch clearance from the finished grade to the bottom edge of the siding. This prevents moisture from the ground from being absorbed by the siding.

- Slabs, Paths, Steps: Maintain a minimum 2-inch clearance from any concrete slabs, paths, or steps to the siding.

- Roof-to-Wall: At any point where a roof meets a wall, a minimum 2-inch clearance is required between the roof surface and the siding. Proper kickout flashing must also be installed to divert water away from the wall at roof-to-wall intersections.

- Decks: For decks, we maintain a minimum 1-inch clearance between the deck surface and the bottom edge of the siding.

- Gutters: Ensure at least a 1/4-inch clearance between gutters and the siding.

- Windows and Doors: All windows and doors require proper flashing around their perimeters to prevent water intrusion. Trim blocks are needed around penetrations 1.5 inches or larger, such as hose bibs or dryer vents.

- Mortar/Masonry: A minimum 1/4-inch clearance should be maintained where siding meets mortar or masonry surfaces.

These clearances, combined with carefully installed flashing, create a robust defense against water damage, a common concern in the varied Pennsylvania weather.

Finishing Touches: Painting, Caulking, and Clean-Up

After the hardie board sheet siding installation is complete, the final steps of painting, caulking, and meticulous clean-up bring your home’s exterior vision to life. These finishing touches are not just about aesthetics; they are crucial for protecting the fiber cement and ensuring the long-term performance and warranty of your James Hardie siding.

Painting and Caulking Primed HardiePanel

If you’ve chosen primed HardiePanel siding, painting is a crucial step that we handle with expertise:

- Timely Painting: Factory-primed James Hardie products must be painted within 180 days of installation. For unprimed products, painting should occur within 90 days. This timeframe is essential to protect the material.

- Paint Type: We exclusively use 100% acrylic topcoats on James Hardie products. It’s vital to avoid stains, oil/alkyd base paints, or powder coatings, as these are not compatible with fiber cement and can void the warranty. If the siding is sprayed, back-rolling is recommended to ensure even coverage and proper adhesion.

- Cut Edge Treatment: All field-cut edges must be caulked, painted, or primed. This seals the raw fiber cement, protecting it from moisture absorption.

- Caulking: For joints that are intended to be caulked (and not covered by battens or jointers), we use an elastomeric joint sealant complying with ASTM C920 Grade NS, Class 25 or higher, or a latex joint sealant complying with ASTM C834. These sealants provide the necessary flexibility to accommodate slight movements in the building without cracking.

Special Considerations for ColorPlus® Technology

James Hardie’s ColorPlus® Technology offers a durable, factory-applied finish that simplifies the painting process, but it does have its own set of unique handling and maintenance requirements:

- Laminate Sheet Removal: ColorPlus® products often come with a protective laminate sheet. This sheet must be removed immediately after the installation of each course to prevent it from baking onto the siding.

- Cleaning Residue: Any residue or dust on ColorPlus® products should be wiped off with a wet soft cloth or brush and then rinsed with a garden hose. Avoid harsh chemicals or abrasive cleaners.

- Edge Coaters: For non-factory cut edges that are not terminated into trim, we use specific ColorPlus® Technology edge coaters. These match the factory finish and maintain the product’s aesthetic and protective qualities.

- Touch-Up Kits: For minor nicks, scrapes, or nail heads, we use James Hardie’s ColorPlus® Technology touch-up applicator sparingly. If large areas are damaged, the recommendation is to replace the damaged section of siding rather than attempt extensive touch-ups, as third-party products can void the warranty. Nail heads on ColorPlus products should not be caulked; touch-up kits are used for these.

- Repainting Procedures: While ColorPlus is designed for long-lasting color, if repainting becomes necessary, the surface must be thoroughly cleaned, dried, and free of dust, dirt, or mildew. Repriming is usually not required. Again, 100% acrylic topcoats are recommended, and painting should never occur when the product is wet.

For inspiration on colors and finishes, our guide on Choosing James Hardie Colors for Your Home can help you visualize the final look.

Frequently Asked Questions about Hardie Board Sheet Siding Installation

We often hear similar questions from homeowners in Hatfield, Trooper, and other Pennsylvania communities considering hardie board sheet siding installation. Here, we address some of the most common inquiries to help you better understand the process.

What are the main differences between installing on a single-family home versus a commercial building?

While the core principles of HardiePanel installation remain consistent, there are specific considerations that differentiate single-family home projects from multi-family or commercial ones:

- Installation Guides: James Hardie provides separate installation instructions. One set focuses on single-family installations, while another details requirements for multi-family/commercial projects. This immediately tells us that there are nuances.

- Drainage Requirements: For multi-family and commercial projects, especially in moist or severe wind-driven rain climates (like parts of Pennsylvania), drainage requirements can be more stringent. This might involve specific rainscreen systems with minimum 3/8 inch air gaps, or drainage planes with 90% efficiency.

- Wind Load Considerations: James Hardie provides installation and wind load information for buildings with a maximum mean roof height of 85 feet. For installations above 60 feet, specific technical support from James Hardie is required. Commercial buildings are more likely to exceed this height, necessitating additional engineering and fastening schedules.

- Substrate and Framing: While both can use wood or steel studs, commercial projects might have more complex framing systems or non-nailable substrates, requiring specialized fastening techniques outlined in technical bulletins.

- Building Codes: Multi-family and commercial projects often fall under stricter building codes (e.g., IBC vs. IRC) and may require additional approvals or inspections from local authorities.

You can review specific installation guidelines for different applications, such as those found in HardiePanel Installation Inst_HZ5-HR .

Can I install HardiePanel siding myself?

While some homeowners might be tempted to tackle a hardie board sheet siding installation as a DIY project, we strongly recommend against it. Here’s why:

- Complexity: As this guide illustrates, HardiePanel installation involves numerous precise steps, from substrate preparation and flashing details to specific fastening techniques and silica dust safety protocols. It’s an intricate process that requires a deep understanding of building science and James Hardie’s strict guidelines.

- Required Tools: The installation demands specialized tools, including a circular saw with a HardieBlade and a dust collection system, pneumatic nailers, and specific types of fasteners and sealants.

- Safety Risks: The most significant risk is exposure to respirable crystalline silica dust during cutting, which can cause serious health problems. Professionals are trained in OSHA-compliant safety practices and proper dust mitigation.

- Warranty Implications: James Hardie’s warranty can be affected by improper installation. As a homeowner, you’ll work with a contractor who facilitates the installation. James Hardie explicitly states that “failure to follow James Hardie written installation instructions… may affect warranty coverage.”

- Value of Professional Installation: James Hardie encourages homeowners to work with professional contractors for optimal product performance. We have dozens of installation specialists throughout the U.S. and Canada, including here in Pennsylvania, who are available to work with you. These specialists are trained and certified to ensure your siding is installed correctly, providing lasting protection and maximizing your investment.

- Time and Effort: Even for experienced DIYers, installing siding is a massive undertaking that can take weeks or months. Professionals complete the job efficiently and correctly the first time.

When it comes to protecting your home, entrusting your siding project to a certified professional is the smartest choice. You can locate a contractor near you through James Hardie’s network.

How much does a siding replacement cost?

The cost of a siding replacement, particularly for hardie board sheet siding installation, can vary significantly based on several factors:

- Material Choice: While HardiePanel offers exceptional value, different textures or finishes (like ColorPlus® Technology) can influence the per-square-foot cost.

- Project Complexity: The architectural style of your home plays a big role. Homes with many corners, gables, windows, or intricate details will require more labor and specialized cuts than a simple, rectangular structure.

- Labor Costs: Skilled labor is a significant component of the overall cost. Professional installers, especially James Hardie Elite Preferred Contractors like us, bring expertise, efficiency, and adherence to manufacturer guidelines, which ensures a quality installation that lasts.

- Substrate Condition: If your existing sheathing or framing needs extensive repairs or replacement before the new siding can go on, this will add to the total cost.

- Disposal: The cost of removing and disposing of old siding material is also factored in.

- Additional Features: Any extra features, such as new trim, soffits, or specialized flashing, will contribute to the final price.

Given these variables, providing a single price is impossible. However, we’ve put together a comprehensive resource on How much does a siding replacement cost in PA? that can help you understand the investment involved for your home in Buckingham, Jamison, or elsewhere in our service areas.

Achieve a Flawless Finish with Professional Installation

Starting on a hardie board sheet siding installation project is a significant investment in your home’s future. As we’ve explored, it’s a process rich in critical details—from meticulous preparation and precise cutting to proper fastening, joint treatment, and crucial clearances. Each step is vital for ensuring the longevity, performance, and aesthetic appeal of your HardiePanel siding.

The superior durability of James Hardie fiber cement, especially against Pennsylvania’s diverse climate, is undeniable. But that durability is only fully realized when the product is installed according to the manufacturer’s rigorous standards. Neglecting any of these steps can compromise your home’s weather protection, potentially lead to costly repairs, and even void your warranty.

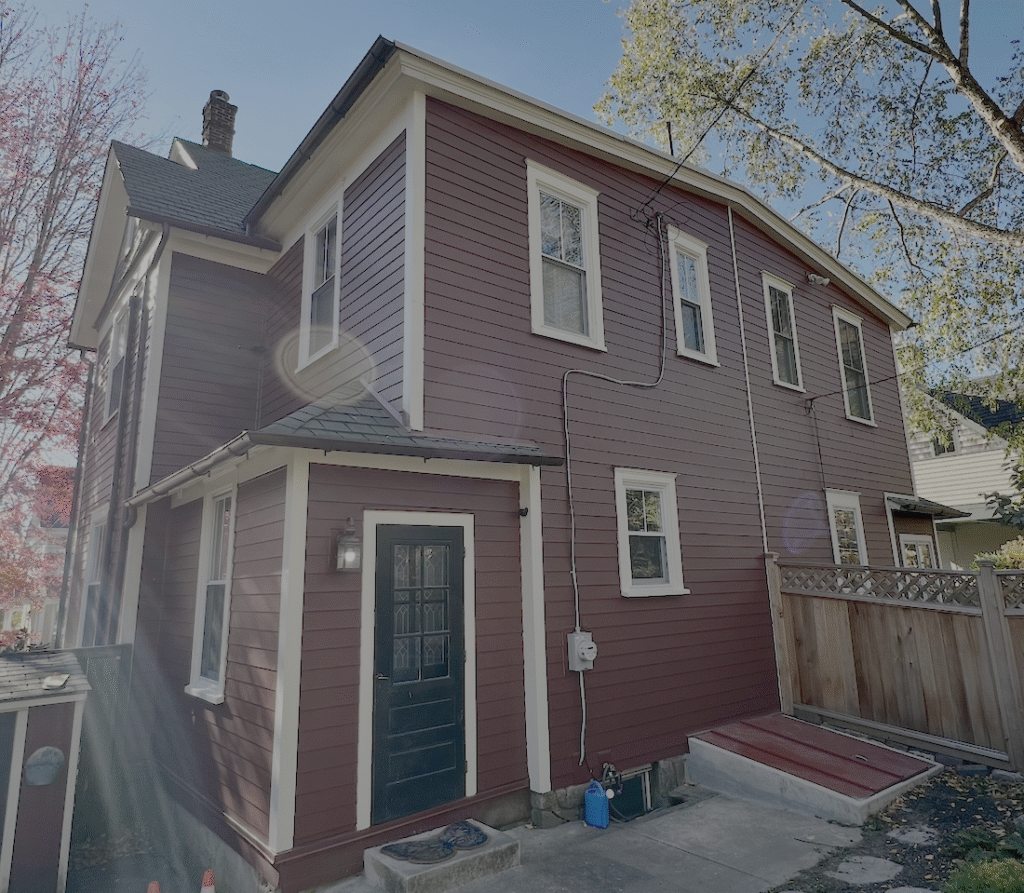

At Kesting Construction, we pride ourselves on exceptional craftsmanship, guaranteed quality, and superior customer service. As a James Hardie Elite Preferred Contractor, we bring unparalleled expertise to every project, ensuring your Hardie board sheet siding installation is executed flawlessly. Our team is trained in the latest James Hardie installation techniques and safety protocols, guaranteeing long-lasting protection and stunning curb appeal for your home in Harleysville, Yardley, Montgomery County, or any of our service locations.

Don’t leave the integrity of your home to chance. Partner with professionals who understand the nuances of fiber cement siding and are committed to delivering a perfect finish.

Ready to transform your home with durable, beautiful HardiePanel siding? Explore our James Hardie Siding services and let us help you achieve a flawless, chic exterior that will stand the test of time.